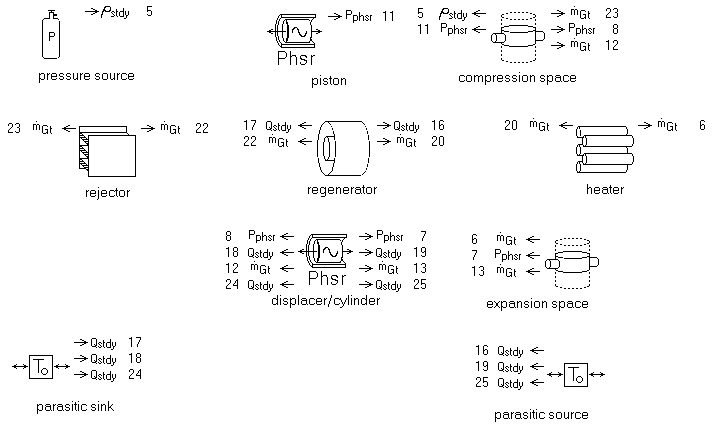

A generic free-piston stirling engine model. The three main heat exchangers are represented in the second row, connected by like-numbered arrows. The piston and displacer provide volume displacements to the compression and expansion spaces which are also connected to the heat exchangers. The pressure source establishes the mean cycle pressure and the components in the bottom row anchor the ends of various cylinder walls for purposes of modeling parasitic thermal conduction losses.

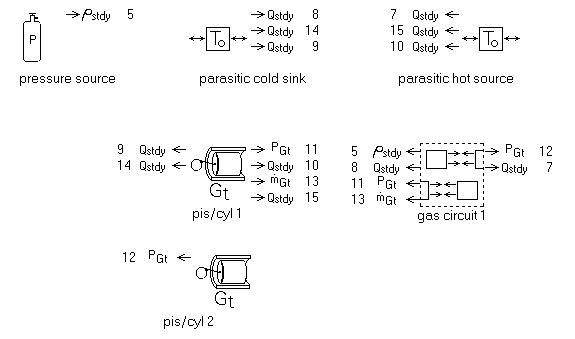

A generic double acting stirling engine model. This level shows two pistons (phase-shifted by 90 degrees) driving a single gas circuit, encapsulated in a submodel which contains additional model components representing heat exchangers, etc.

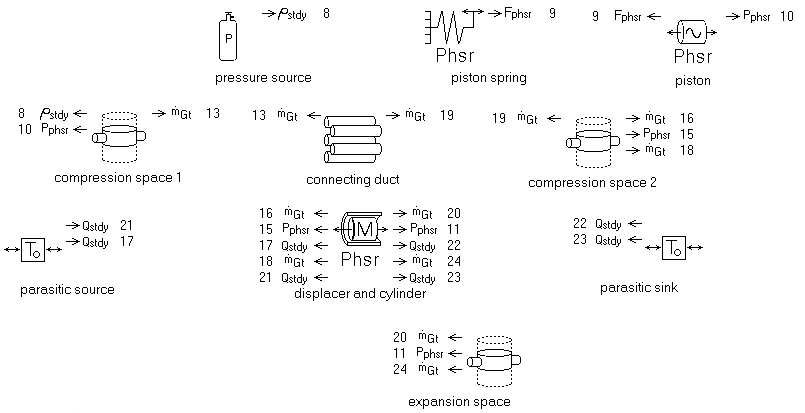

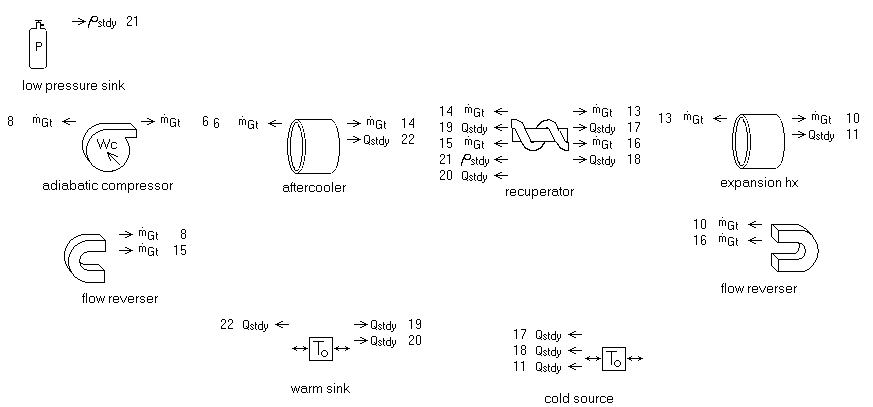

A generic split-cycle stirling engine model. Similar to the free-piston stirling engine model except there are two compression spaces. The piston provides a volumetric displacement to the first one, resulting in gas flowing though a connecting duct to the second one. A displacer inside the displacer and cylinder component provides a volumetric displacement to the second compression space.

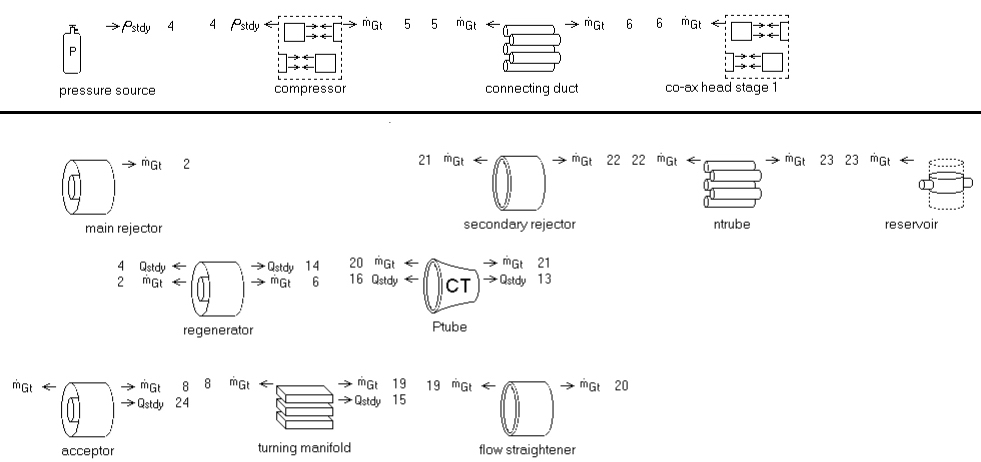

Components above the bar represent the main functional elements of a single-stage split-cycle pulse-tube cryocooler. Components below the bar are those within the "co-ax head stage 1" of the main window. They represent a co-axial cold-head arrangement. Two and Three stage models are possible by creating additional cold-head components.

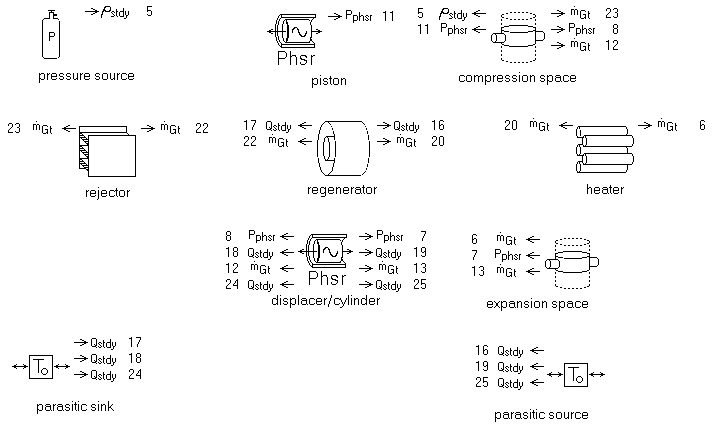

A generic Joule-Thomson cryocooler model. A closed-cycle steady-state model in which the adiabatic compressor component drives high-pressure gas flow through an aftercooler, then a recuperator. The expansion hx serves as expansion valve and cold heat exchanger. A flow reverser diverts the low-pressure gas stream back through the recuperator and another flow reverser feeds it back into the compressor.